Uhlelo Lokuhlola Injoloba

Imidiya yokuhlola iyingxenye ebalulekile yemishini yokuhlola. Uma isikrini sokudlidliza sidlidliza, ngokusebenzisa izimo ezihlukene nosayizi bejiyomethri nangaphansi kwesenzo samandla angaphandle, impahla eluhlaza izohlukaniswa futhi kuzuzwe injongo yokugreda. Zonke izinhlobo zezinto ezibonakalayo, ukwakheka okuhlukile nezinto ezibonakalayo zephaneli yokuhlola noma ukungezwani kanye nemingcele ehlukahlukene yomshini wokuhlola kunomthelela othile ekhonweni lesikrini, ukusebenza kahle, izinga lokugijima kanye nempilo. Izinto ezisetshenziswayo ezahlukahlukene, izindawo ezahlukahlukene, kufanele zikhethe imikhiqizo yemidiya yokuhlola ehlukile ukuze kuzuzwe umphumela ongcono wesikrini.

Kuya ngemishini ehlukene, imfuneko kanye nezimo, imidiya yokuhlola ingahlukaniswa ngochungechunge olungezansi

1.Uchungechunge lwe-Modular

2.Tension series

3.Uchungechunge lwephaneli

Ukuxhumana nemishini ngokuvamile kuhlukaniswe: uxhumano lwe-mosaic, uxhumano lwe-bolt, uxhumano lwebha yokucindezela, uxhumano lwe-hook yokuhlola njalonjalo.

Izicelo zezimayini

1.Pre-grinding ore

2.Pre- heap leach

3.Insimbi enensimbi enezinga eliphezulu

4.Mill ukukhipha izikrini

5.Amasekhethi emidiya aminyene

6.Control screening - ukususwa inhlawulo

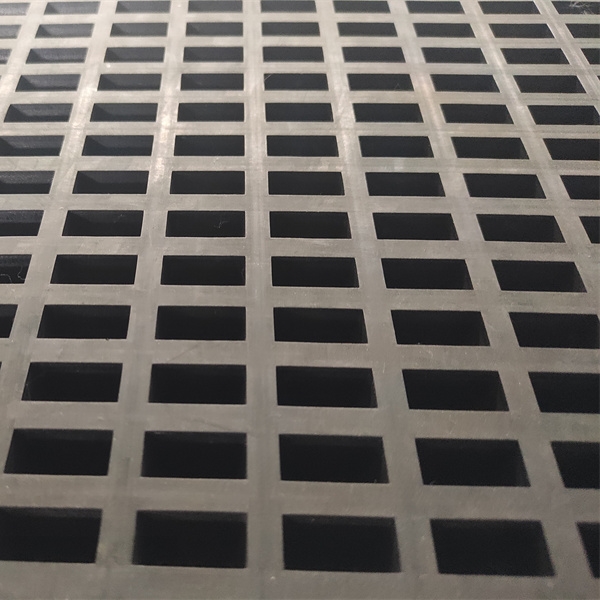

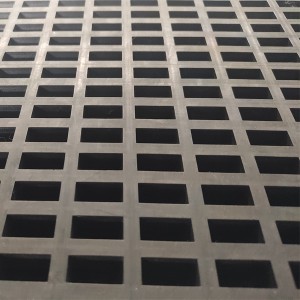

Isistimu yesikrini senjoloba ihlukile ekwakhiweni kwesakhiwo, ngaphezu kokusetshenziswa kwenqubo yokubumba irabha ephezulu engagqoki (le nqubo igwema indlela yokubhoboza yendabuko enqubweni yomonakalo womkhiqizo), umkhiqizo awugcini nje ngokuba ne-porosity ephezulu, kodwa futhi inokuvulwa komfaniswano. Ubambo lwesikhala alusoze lwaphuka. Uma kuqhathaniswa nezikrini zezintambo, ezinendawo yokuhlola ephansi yokuvula ezindaweni ezincane. Omata bethu bokuhlola injoloba bakhiwe ngezinto eziqinile ezingagugi, bafaneleka njengamadekhi aphelele emabhokisini amakhulu esikrini noma njengengxenye yomthelela. Lezi zikrini zitholakala ebangeni lesikwele noma izimbobo ezigobile ukuze zivumelane nazo zonke izinhlobo zezimfuneko zokugreda. Inzuzo yomata besikrini senjoloba isikhathi eside kakhulu sokuphila kanye namazinga omsindo ancishisiwe. Isikrini se-Rubber tension sifaneleka kakhulu kuzinhlelo zokusebenza zokuhlola ezimahhadlahhadla ukuya kwezicolekileyo. Ukusetshenziswa kwerabha kuzonciphisa umsindo, kunciphise ukuvinjelwa futhi kunikeze amakhono akhethekile okugqoka. Omata be-screen cross tension mats bakhiwa kusetshenziswa izendlalelo ezingu-2 zerabha ekwazi ukumelana nekhwalithi ephezulu enokuqiniswa kwentambo phakathi kwezendlalelo. Osayizi abenziwe ngokwezifiso nesimo sokusebenza nakho kuyatholakala uma ucelwa.

Uchungechunge lwesikrini sephaneli yerabha

Uchungechunge lwesikrini se-Rubber tension

Ipharamitha esebenzayo yemikhiqizo yokuhlola iraba

| Impahla | Amayunithi | Inani |

| Ukuqina | Shore A | 63 |

| Amandla aqinile | I-MPa | 19±10 |

| Phula elongation | % | 660±10 |

| Amandla izinyembezi | N/mm | 313 |

| Ukulahlekelwa kwe-abrasion | % | 37 |

| Amazinga okushisa okusebenza | -30 ℃ ukuze + 60 ℃ | |

| Umbala | Mnyama |

Izici

1.High screening ukusebenza kahle

2.Akukho ukuxhunywa kwesikrini

3.Impilo ende yesevisi

4.Ukumelana nowoyela

5.Ukumelana nokugqwala

6.Ukumelana nokugqoka